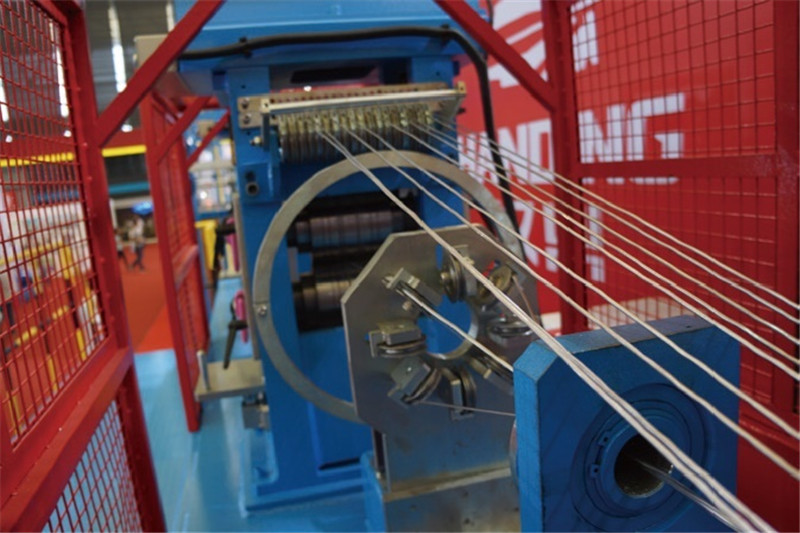

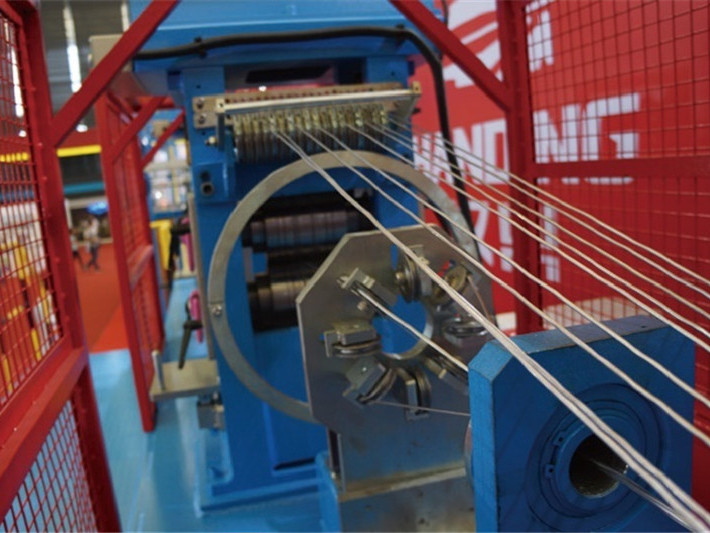

Double Twist Bunching Machine

Double Twist Bunching Machine

Para sa precision control at madaling operasyon, ang AC technology, PLC at inverter control at HMI ay inilalapat sa aming double twist bunching machine. Samantala, ginagarantiyahan ng iba't ibang proteksyon sa kaligtasan ang aming makina na tumatakbo nang may mataas na pagganap.

1. Double Twist Bunching Machine (Modelo: OPS-300D- OPS-800D)

Application: Pangunahing angkop para sa pag-twist sa itaas ng 7 strands ng silver jacketed wire, tinned wire, enameled wire, bare copper wire, copper-clad steel, copper cladding aluminum, atbp. Kaliwa o kanang direksyon ng twisting ay malayang mapipili.

| Modelo | OPS-300D | OPS-400D/ OPS -500D | OPS-630D | OPS-800D | OPS-800D |

| spool dia.(mm) | 300 | 400-500 | 630 | 800 | 1000 |

| max na bilis ng pag-ikot (rpm) | 3000 | 3000 | 2000 | 2000 | 1500 |

| feeding wire dia. (mm) | 0.05-0.28 | 0.08- 0.45 | 0.12- 0.62 | 0.2-1.04 | 0.45-2.52 |

| twist cross section(mm²) | 0.035-0.45 | 0.035-2.5 | 0.18-6.0 | 0.8-16 | 6-35 |

| haba ng lay(mm) | 10 Segment3.65-17.15 | 40 Segment6.3-50.4 | 34 Segment11.15-100 | 30 Segment20-160 | 34 Segment20-300 |

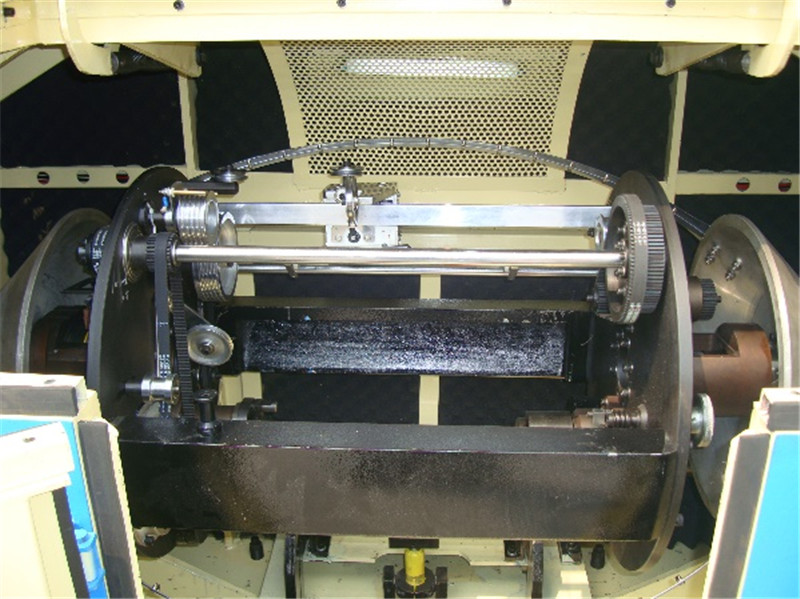

2, Double Twist Bunching Machine (Modelo: OPS-1250D - OPS -2500D)

Application: Pangunahing angkop para sa twisting copper wire, aluminum wire o PVC insulated wire sa ibaba ng 7/19/37/61 strands sa concentric twisting wire.

| Modelo | OPS-1250D | OPS -1600D | OPS -1800D | OPS -2000D | OPS -2240D | OPS -2500D |

| max. spool dia.(mm) | 1250 | 1600 | 1800 | 2000 | 2240 | 2500 |

| max. bilis ng linya(m/min) | 70-150 | 170-200 | 170-200 | 170-200 | 170-200 | 170-200 |

| max na bilis ng pag-ikot (rpm) | 800 | 600 | 350 | 350 | 300 | 300 |

| feeding wire dia. (Al/Cu) (mm) | 1.0-3.0 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 | 1.5-4.8 |

| stand cross section(mm²) | 3.5-70 | 16-240 | 16-240 | 16-240 | 16-240 | 16-240 |

| seksyon ng compacting (Cu) ( mm²) | 3.5-50 | 16-150 | 16-185 | 16-240 | 16-300 | 16-300 |

| seksyon ng compacting (Al) ( mm²) | 3.5-70 | 16-240 | 16-240 | 16-300 | 16-400 | 16-400 |

| haba ng lay(mm) | 40-350 | 40-350 | 50-600 | 60-600 | 60-600 | 60-600 |

| max. strand panlabas na dia. (mm) | 15 | 25 | 35 | 35 | 35 | 35 |